PRODUCTS

PACKERS

MECHANICAL MODERNIZED PACKERS OF 2 PVM AND 3 PVMMECHANICAL MODERNIZED PACKERS OF 4 PVM TYPE

PACKER PGPM1

PACKER PDM1

HYDRAULIC PACKER PV-YaG-N-122-30

HYDRAULIC PACKER PGM-195

DRILLABLE REMOVABLE PACKER PRS-195

RETRIEVABLE PACKER PGE-1

PLUG PACKER PPM2

RETRIEVABLE TWO-SECTION PACKER FOR SELECTIVE WORKS SPM

ANCHOR 2 YaG

|

Mechanical modernized packers of 2 PVM and 3 PVMMechanical modernized s of 2 PVM and 3 PVM types are designed for sealing of tubing and drill pipes in well casing string during operations connected with stimulation of formation and can be used in all macroclimatic regions in accordance to GOST 16350-80. |

| Specifications | 2PVM- 118-50 | 2PVM- 122-50 | 2PVM- 136-50 | 2PVM- 140-50 | 3PVM- 118-50 | 3PVM- 122-50 | 3PVM- 136-50 | 3PVM- 140-50 |

| Outer diameter, D, mm | 118 | 122 | 136 | 140 | 118 | 122 | 136 | 140 |

| Max parcker axial force, kN: -at setting -at releasing | 150 80 | 150 80 | 150 80 | 150 80 | 150 80 | 150 80 | 150 80 | 150 80 |

| Pressure difference, MPa, no more than | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| Passage diameter, mm, no less than | 50 | 50 | 60 | 60 | 48 | 48 | 59 | 59 |

| Passage diameter of casing pipes, mm, no less than | 146 | 146 | 168 | 168 | 146 | 146 | 168 | 168 |

| Max. inner diameter of production strings in which disconnection sealing is provided, mm | 127.1 | 130.7 | 144.1 | 147.1 | 127.1 | 130.7 | 144.1 | 147.1 |

| Operating environment temperature, °C, no more than | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 |

| Overall dimensions, mm: diameter D1 | 133 | 133 | 147 | 150 | 140 | 140 | 160 | 160 |

| length L | 725 | 725 | 740 | 740 | 910 | 910 | 965 | 956 |

| Weight, jkg: of packer | 25 | 26 | 32 | 34 | 28 | 28.5 | 35 | 35.5 |

| of complete set | 29 | 31 | 37 | 39 | 32.5 | 33 | 41 | 41.5 |

| Seal cup, pcs | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 |

| Slip, pcs | 6 | 6 | 6 | 6 | 4 | 4 | 4 | 4 |

|

Mechanical modernized packers of 4 PVM typeMechanical modernized packers of 4 PVM type are designed for sealing of tubing and drill pipes in well casing string during operations connected with stimulation of formation and can be used in all macroclimatic regions in accordance to GOST 16350-80. |

| Specifications | 4PVM-118-50 | 4PVM-122-50 | 4PVM-136-50 | 4PVM-140-50 |

| Outer diameter, D, mm | 118 | 122 | 136 | 140 |

| Max pressure difference, MPa | 50 | 50 | 50 | 50 |

| Max parcker axial force, kN - at setting - at releasing | 150 80 | 150 80 | 150 80 | 150 80 |

| Passage diameter, mm, no less than | 48 | 48 | 59 | 59 |

| Connection thread dimension, mm - upper - left-hand in accordance with GOST 631-75 - lower - in accordance with GOST 633-80 | 73L 60 | 73L 60 | 89L 60 | 89L 60 |

| Max operating environment temperature, °C | 150 | 150 | 150 | 150 |

| Max. inner diameter of production strings in which disconnection sealing is provided, mm | 127.1 | 130.7 | 144.1 | 147.1 |

| Casing string passage diameter, mm | 146 | 146 | 168 | 168 |

| Overall dimensions, mm, no more than (diameter D1 x length L) | 135õ840 | 135õ840 | 153õ875 | 153õ875 |

| Packer (complete set) weight, kg, no more than | 27 (31.1) | 27.5 (31.6) | 4 (37.7) | 34.5 (38.2) |

|

|

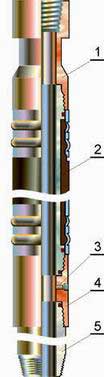

PACKER PGPM1The packer of type PGPM1 is intended for increasing quality of productive formation insulation when fixing the bores in order to prevent cross flows and annular ingressions of formation fluids during cement mortar setting,The parker is lowered in the bore as the part of casing column and installed in the set interval. The construction of packer PGPM1 has a protection system against premature operation of increased reliability. To activate the packer PGPM1 the drop of casing annulus and tubing pressure is not necessary, so, it significantly widens the area of its usage, i.e. the packer may be installed in upper intervals and in so called uncemented sections of bore. In addition, the improved construction of the parker valve unit provides a possibility to activate several packers successively installed at one production string. The distinctive aspect of packers PGPM1 lies in existence of repair and prophylactic additional setting of packer. The system is activated during hydraulic pressuring of cemented casing pipe, it provides a possibility to adjust the sealing ability of packer during exploration or underground repair of bore by dosed increasing of liquid volume in the seal element. Main elements of packer PGPM

|

Specification

| Parameters of | PGPM1-146-1 | PGPM1-168-1 |

| PGPM1-146-2 | PGPM1-168-2 | |

| External diameter of casing pipe, mm | 146 | 168 |

| Maximum pressure drop between unrelated zones

at nominal factor of setting of packer (1.27) MPa | 15,0/17,5* | 15,0/17,5* |

| Diameter of packer pass, mm | 124 | 144 |

| The excessive power inside the seal element during setting of packer in the bore, MPa | 2.15 | 2.15 |

| Maximum factor of setting of packer | 1.45 | 1.45 |

| Maximum working temperature, °Ñ | 100/150* | 100/150* |

| Maximum excess pressure on the body of packer, MPa - internal - external | 35 30 | 35 30 |

| Maximum tensile loading on the body of packer, ts | 85 | 95 |

|

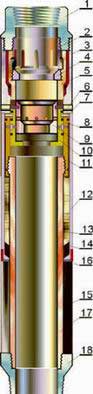

PACKER PDM1The packer of type PDM1 provides double-stage centering of bores accompanied by creation of hermetical bridge above the intake formation.The packer is intended for double-stage or cup cementing of bore with hermetical insulation of lost circulation horizons or producing formations from the casing annulus of bore placed above. The working substance where the packer works in the bore –mineralized brine water, oil and gas, cement slurry or drill mud with the density up to 2.4 g/cm3, treated by chemical reagents. The packer is lowered in the bore as the part of the casing pipe for single-acting usage and works without maintaining and repair. The packers of two-staged and cup cementing PDM are used in the inclined and horizontal bore hole for its cup cementing while completing them with plugs corresponding to these aims. When ordering it is necessary to mention "For horizontal bores". Main elements of packer:

|

| ||

| ||||

| ||||

|

Specification

| Parameters |

Code of article | ||||

| PDM-146 | PDM-146-1 PDM-146-2 | PDM-168-2 | PDM-168-1 | PDM-168-3 | |

| Nominal diameter of casing pipe, equipped with packer, mm | 146 | 146 | 168 | 168 | 168 |

| Maximum external diameter of packer, mm | 177+1,25 | 177+1,25 | 200+1,45 | 198+1,45 | 200+1,45 |

| Length of packer in working position, mm | 3250 | 3320 | 3250 | 3250 | 3320 |

| Length of packer in transportation position, mm | 3360 | 3430 | 3360 | 3360 | 3430 |

| Weight of packer in working position, kg | 190 | 210 | 220 | 230 | 250 |

| Weight of packer in transportation position, kg | 230 | 250 | 270 | 280 | 300 |

| Connection thread as per GOST 632-80 | OTTM-146 | ÎÒÒÌ-146 | ÎÒÒÌ-168 | ÎÒÒÌ-168 | ÎÒÒÌ-168 |

|

HYDRAULIC PACKER PV-YaG-N-122-30It is intended for protection of production casings against impact of injected liquid, as well as for increasing pressure during technological operations intended for impact on the effective drainage area of geological horizon during operation of injection, absorption and faulting wells.It provides operation in the boring casings with a nominal diameter of 146 mm. There is a possibility to install packer at any interval of the production casing. Installation and removing of packer is performed without revolving of flow columns. |

Òåõíè÷åñêèå õàðàêòåðèñòèêè

| Maximum working pressure, kPa | 30 |

| Temperature of working substance, not more than °Ñ | 100 |

| Diameter of packer flow passage, not more than, mm | 50 |

| Diameter of external surfaces of metal parts, not more than, mm | 122 |

| Length, mm | 1500 |

|

HYDRAULIC PACKER PGM-195It is intended for installation in the naked oil and gas wells when exploring and insulating loss zones. It consists of 3 main units: wall-anchored, packing and choke units. |

Decipher of designation:

P – multi-use packer;

GM – way of setting the packer – hydromechanical;

195 – external diameter of packer, mm

16 – maximum pressure drop, sustained by packer, MPa

Specification

| Pressure drop, sustained by the packer, maximum, kgf/cm² (MPa): | 160 (16) |

| Pressure drop during packing, MPa | 2...3 |

| Thrust force on the rubber packing element in the course of packing, minimum, kN | 120 |

| Substance | - power water, clay mud and cement slurry |

| Temperature of working substance, not more than °Ñ | 120 |

| Diameter of packer flow passage, not more than, mm | 80 |

| Diameter of rams in the transportation position, maximum, mm | 193 |

| Exit of rams to the working position, minimum, mm | 230 |

| Connection thread: | 3-147 ÃÎÑÒ 5286-75 |

| Overall dimensions, mm: - external diameter - length | 195 2260 |

| Weight, kg | 172 |

| Weight of complete set, not more, kg | 198 |

|

DRILLABLE REMOVABLE PACKER PRS-195It is used as the sealant for separation of annular space from loss zones while insulating these zones in the bores with a diameter of 216 mm. It is used together with a hydraulic head included in the set of packer PRM-195 instead of the removable packer PRM-195.040-01. To provide a possibility to use the packer with an open channel, it is equipped with the upper bend PRS-195.009 and the end cup PRS-195.100 for silencing the channel of packer mandrel after plugging-back of well.Decipher of designation: |

Specification

| Substance | - power water, clay mud and cement slurry |

| Diameter of packer flow passage, not more than, mm | 95 |

| Diameter of upper bend flow area, mm | 70 |

| External diameter of pump bucket, mm | 195 |

| Connection thread: | trapezoidal one for spinning with hydraulic heads, left Tr 100õ5LH as per GOST9484-81 |

| Pressure inside the hole during packing the packer with a dumped bore: -maximum, kgf/cm2 -minimum, kgf/cm2 | 90 75 |

| Diameter of bore, mm: - maximum - nominal | 224 216 |

| Climatic execution | UHL2 |

| Overall dimensions, mm: - external diameter - length | 200 692 |

| Weight, kg | 31 |

RETRIEVABLE PACKER PGE-1

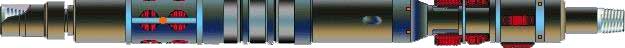

The retrievable packer PGE-1 is a full bore, high performance and installed compressively packer: it is used for squeeze jobs, acid treatment, hydraulic formation breakdown or well test. The packer is equipped with plunger anchor shoes, three element system of packer setting and a release valve of bigger diameter for reliable and accident-free operation. The packer PGE-1 may be lowered independently or with a recoverable temporary plug. Performing repair works in the conditions of high pressure, the packer is kept in the place of seating using the integral hydraulic system of engaged grooves. The pressure which is necessary for operation of the system is not taken off directly from the pump and compressor pipes, but from sealing elements, it prevents its clogging by mud and cement. The parker PGE-1 has an integral sluicing system, providing a possibility to compensate pressure difference in the packer during its removing and providing protection of hydraulic grooves during operation and easier circulation, it has an automatic lock for seating and placing in the transportation position in the bores. The packer may be operated "clockwise" and "anti-clockwise".

Specification

| Designation | External diameter of string, mm |

Internal diameter of string, mm | External diameter of packer, mm |

External diameter of gage rings, mm | Connection threads as per GOST 633-80 |

| PGE-1-104 | 114,3 | 103,9 | 95,3 | 96,5 | Â60 |

| PGE-1-116 | 127 | 115,8 | 101,6 | 108 | Â60 |

| PGE-1-128 | 139,7 | 128,1 | 114,3 | 120,1 | Â60 |

| PGE-1-132 | 146,1 | 132 | 114,3 | 120,5 | Â60 |

| PGE-1-154 | 168,3 | 153,6 | 141,2 | 143,7 | Â73 |

| PGE-1-166 | 177,8 | 166,1 | 146,1 | 158,2 | Â73 |

| PGE-1-178 | 193,7 | 178,4 | 158,8 | 168,3 | Â73 |

| PGE-1-228 | 244,5 | 228,6 | 206,2 | 215,9 | Â89 |

| PGE-1-322 | 339,7 | 322,9 | 295,2 | 307,8 | Â114 |

PLUG PACKER PPM2

The plug packer PPM2 is intended for insulation of annular space in the production casings with the diameter of 140 and 146 mm in order to explore an underlying gas bearing, hydrocarbon or producing formation with its following insulation from the incumbent producing formations. If necessary, the plug packer may be used as the part of bridge plug during the repair of bore, when the pressure drop on the plug packer from below is not higher than 30 MPa.

Specification

| Parameters | Code of article | |

| PPM2-140 | PPM2-146 | |

| Nominal diameter of casing pipe, mm | 140 | 146 |

| Minimal internal diameter of boring casing, mm | 118 | 124 |

| Maximal internal diameter of boring casing, mm | 127 | 132 |

| Depth of installation, m | 0-5000 | 0-5000 |

| Maximal pressure drop between the disengaged zones in the production string, MPa | 30 | 30 |

| The biggest external diameter of plug, mm | 112 | 118 |

| The smallest internal diameter of plug, mm | 20 | 20 |

| Weight of plug packer, kg | 23,2 | 24,8 |

RETRIEVABLE TWO-SECTION PACKER FOR SELECTIVE WORKS SPM

The selective integral packer is used for insulation of perforation with a specified length while performing stimulation operations and testing of bores. The assembly is lowered in the bore with a switched off bypass element above or below perforation. Rotation of pipes NKT to the left side results in closing of the bypass and engaging with the string by lower slips. The required weight of pipe, assigned to the packer, is packering the space by rubber elements. The assembly may be pressure-tested in the non-perforated string. The packer is placed in the transportation position, by raising the pipe and revolving it to the right, in order to close the circulation valve and to install lower grooves in the transportation position. If necessary, the bypass element may be opened for circulation of liquid through the packer. Reinstallation of packer in the incumbent intervals may be performed by raising the tool and by its loading to start operation once again. To install the packer in the underlying interval it is necessary to remove the packer and to install it in the transportation position for moving it down.

Specification

| Designation | External diameter of string, mm |

Internal diameter of string, mm |

External diameter of packer, mm |

External diameter of gage rings, mm |

Connection threads as per GOST 633-80 |

| SPM-104 | 114,3 | 103,9 | 95,3 | 96,5 | Â60 |

| SPM-116 | 127 | 115,8 | 101,6 | 108 | Â60 |

| SPM-128 | 139,7 | 128,1 | 114,3 | 129,1 | Â60 |

| SPM-154 | 168,3 | 153,6 | 141,2 | 143,7 | Â73 |

| SPM-166 | 177,8 | 166,1 | 146,1 | 158,2 | Â73 |

| SPM-228 | 244,5 | 228,6 | 206,2 | 215,9 | Â89 |

| SPM-322 | 339,7 | 322,9 | 295,2 | 307,8 | Â114 |

| ANCHOR 2 YaGThe anchor 2YaG is intended for keeping the packer at the place of installation while performing repair operations in the bores and operations connected with impact on the geological horizon in all macroclimate regions as per GOST 16350-80. |

| Specification | 2YaG-118-50 | 2YaG-118-50 |

| External diameter, mm | 118 | 136 |

| Pressure drop, MPa | 50 | 50 |

| Nominal diameter of casings, mm | 146 | 168 |

| Maximal internal diameter of boring casings, mm | 127,7 | 144,1 |

| Maximal axial load, perceived by the anchor at 50 mPa, kNt | 750 | 750 |

| Diameter of orifice, mm | 50 | 62 |

| Temperature of working substance, °Ñ | 150 | 150 |

| Length, mm | 510 | 510 |

| Weight, kg | 2,3 | 25 |