PRODUCTS

SCRAPERS

SR – TELESCOPIC SCRATCHER FOR NKTSK – MECHANICAL UNIVERSAL CASING SCRAPER

SKK – COMBINED CASING SCRAPER

SGM – UNIVERSAL HYDROMECHANICAL SCRAPER

SG - HYDRAULIC SCRAPER

S - MECHANICAL SCRAPERS

SÌ è SKR - SCRAPER

SR – TELESCOPIC SCRATCHER FOR NKT

It is intended for mechanical cleaning of NKT internal surface with diameters of 60, 73 and 89 mm from organic and inorganic deposits on the bores equipped with electric submergible buried centrifugal pumps. The scratcher differs in the fact that cleaning of pipe does not require forced pressing of knives to the internal wall of NKT – the knives are pressed independently by means of the construction of the scratcher and grinding of knives. While lowering in the pipe, the scratcher is folded to provide idle running and while raising it is opened for cleaning the pipe. The deposits separated from the walls of NKT are lifted out from the bore with oil stream. If there is a necessity to increase effectiveness of cleaning, the scratcher is composed of two cutting sections. To simplify lowering of the scratcher, the heavy loader is fixed to it. Completeness: scratcher, heavy loader.

Specification

| Type of scratcher SR | SR | ||

| Nominal diameters of cleaned pipes, mm | 60 | 73 | 89 |

| Number of knives on the scratch, pcs | 2 | ||

| Number of blades on the knife, pcs | 1 | ||

| Diameter of knife output, mm | 44 | 56 | 70 |

| Overlapping factor of cleaned surface | 1,1 | ||

| Length, cm | 159 | 177 | 177 |

| Weight, kg | 7,6 | 9,8 | 12 |

SK – MECHANICAL UNIVERSAL CASING SCRAPER

It is intended for removing corrosion, clay coating, cement lining, paraffin deposits from the internal walls of casings with the nominal diameter of 127, 140, 146, 168 mm. Construction of scraper foresees a possibility to perform smooth adjustment of knives' hold down. Completeness: scraper, additional springs – 18 pcs.

Specification

| Type of scraper | SK | ||

| Nominal diameters of cleaned pipes, mm | 140/146 | 168 | - |

| Knife hold-down kgf | 91÷1021 | 98÷1091 | 98÷1091 |

| Adjustment of hold-down | exists | ||

| Type of contact springs | bladed | ||

| Number of springs on the knife, pcs. up to | 10 | ||

| Number of knives on the scraper, pcs | 6 | ||

| Number of blades on the knife, pcs | 6 | ||

| Hold-down of one blade, kgf | 15÷17 | 16÷18 | 16÷18 |

| Diameter of orifice: - thread NKT-73 GOST 633-80 - thread 3-76 GOST R50864-96 | 45 32 | ||

| Diameter of knife output, mm | 100÷116 | 117÷134 | 140÷157 |

| Overlapping factor of cleaned surface | 1,1 | ||

| Length, cm | 69 | 77 | 77 |

| Weight, kg | 37 | 43 | 55 |

SKK – COMBINED CASING SCRAPER

It is intended for removing corrosion, clay coating, cement lining, paraffin deposits from the internal walls of casings with the nominal diameter of 140, and 146 mm. Various elements may be installed on the combined scraper: knives and/or brushes. The knives with a sharpening angle of 15 are foreseen for removing paraffin and gum residues and the knives with a sharpening angle of -3 are foreseen for removing solid layers. The brushes are used in capacity of preliminary detacher. The most effective cleaning of pipes, made of paraffin, is achieved by simultaneous installation of brushes and knives on the scraper: knives loosen paraffin, and knives cut it. Completeness: two sets of brushes and knives for boring casings with the diameter of 139.7 and 146 , casing centralizer intended for cleaning by brushes without knives.

Specification

| Type of scraper | SKK | |

| Nominal diameters of cleaned pipes, mm | 140 | 146 |

| Hold-down of knife | 40÷75 | |

| Adjustment of hold-down | exists | |

| Type of contact springs | twisted | |

| Number of springs on the knife, pcs | 5 | |

| Number of knives on the scraper, pcs | 8 | |

| Number of blades on the knife, pcs | 1 | |

| Hold-down of one blade, kgf | 40÷75 | |

| Diameter of orifice: -thread NKT-73 GOST 633-80 - thread Z-76 GOST R50864-96 | - 32 | |

| Diameter of knife output, mm | 116÷134 | |

| Overlapping factor of cleaned surface | 1,1 | |

| Length, cm | 77 | |

| Weight, kg | 42 | 46 |

SGM – UNIVERSAL HYDROMECHANICAL SCRAPER

It is intended for removing corrosion, clay coating, cement lining and ASPO. In comparison with universal mechanical scrapers of series SK, the scrapers of series SGM differ by improved ability due to reliable hold-down knives, brought forward by the pistons under action of circulation fluid pressure drop.

To increase the endurance, the blades of scraper may be reinforced by hard alloy of mark VK8 or VK8 VK.

Completeness: scraper, throttle adaptor, delivery valve

Specification

| Type of scraper SGM | SGM |

| Nominal diameters of cleaned pipes, mm | 140/146 |

| Hold-down of knife | 0÷600 |

| Adjustment of hold-down | exists |

| Type of contact springs | liquid |

| Number of springs on the knife, pcs | 2 |

| Number of knives on the scraper, pcs | 6 |

| Number of blades on the knife, pcs | 4 |

| Hold-down of one blade, kgf | 0÷150 |

| Diameter of orifice: - thread NKT-73 GOST 633-80 - thread Z-76 GOST R50864-96 | - 30 |

| Diameter of knife output, mm | 118÷134 |

| Overlapping factor of cleaned surface | 1,2 |

| Length, cm | 140/102 |

| Weight, kg | 76/70 |

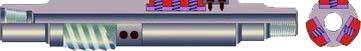

SG - HYDRAULIC SCRAPER

PURPOSE:

The hydraulic scrapers are intended for cleaning of internal surface of boring casings or pump and compressor strings from perforation burrs, rust, cement case, paraffin and other deposits.

STRUCTURE:

The scraper represents a non-detachable tubular case at the upper and lower ends of which executed the socket and nipple connection threads. Six blades with a wear resistant heat treated surface of cutting edges of segment type, which may move radially, are installed in the longitudinal groove of body. The construction of blade teeth is spiral. The blades are kept in the grooves of the body by the spliced ring, fixed by four screws. The piston activates the blades through the spring under the pressure of circulation fluid extending and pressing them to the cleaned surface, so providing full contact. At the same time, sliding along the cleaned surface, the blades cut bumps and contaminations. The spring provides the backward motion of blades. There are left and right hydraulic scrapers. Cleaning of string is performed in the course of lowering the scraper into the bore at the drill or pump and compressor pipes with following rising, lowering and revolving of the tool.

Specification

| Code of scraper standard size | SG-168 |

| Nominal diameter of pipes in the cleaned string, mm | 168 |

| External diameter of scraper body , mm | 138 |

| Diameter of flushing port, mm | 32 |

| Length, mm | 800 |

| Connection thread, GOST R 50864-96 | Ç-76 |

S - MECHANICAL SCRAPERS

The scraper is intended for cleaning of internal surface of boring casings or pump and compressor strings from perforation burrs, rust, cement case, paraffin and other deposits.

The scraper represents a non-detachable tubular case at the upper and lower ends of which executed the socket and nipple connection threads. Six blades with a wear resistant heat treated surface of cutting edges of segment type, which may move radially, are installed in the longitudinal groove of body. The forces pressing blades to the surface of cleaned pipe are created due to impact of pressed springs (three springs for one blade). The blades are placed on the body in two levels with three pieces at each one, providing cleaning of whole perimeter of the pipe's internal surface. The blades are kept in the grooves of the body by the spliced ring, fixed by four screws. Cleaning of the string is performed while lowering the scraper in the bore at the drill or pump and compressor pipes, sliding along the cleaned surface, the blades cut bumps and contaminations.

Specification

| Code of standard size | S-60 | S-73 | S-89 | S-102 | S-114 | S-140 | S-168 | S-194 | S-245 | S-340 |

| Nominal diameter of cleaned string | 60 | 73 | 89 | 102 | 114-127 | 140-146 | 168-178 | 194-219 | 245-273 | 340 |

| Working range at the internal diameter of the string, mm | 48…52 | 56…62 | 71…81 | 85…92 | 93…108 105…120 | 115…130 122…137 | 140…157 152…169 | 172…184 198…210 | 213…236 | 306...330 |

| External diameter of the scraper body, mm | 46 | 53 | 66 | 79 | 88 | 112 | 137 | 154 | 205 | 276 |

| Diameter of water port, mm | 10 | 12 | 12 | 12 | 28 | 32 | 38 | 58 | 60 | 89 |

| Connection thread | 3-30 | 3-88 | 3-44 | 3-44 | 3-50 | 3-76 | 3-88 | 3-117 | 3-133 | 3-152 |

SCRAPER SM and SKR

The scrapers SM-146 and SM-168 are intended for cleaning internal surfaces of boring casings, oil, water and gas bores with the diameters of 146 mm and 168 mm respectively from the corrosion products, hardened crust of drill fluid and cement grouts, traces of perforation and other depositions, as well as for recovery of the well bore passability in the internal diameter. The scrapes are operated in the medium of drill fluid. water, oil and mineralized formation fluid with the temperature up to 100 °C, in the moderate and cold climate zones as per GOST 16350-80. The extensible casing scrapers SKR-60 and SKR-73 are intended for deparaffination of pipes in the fountain, compressor and oil bores equipped by submerged electric-driven pumps.

Specification

| Parameters | Code of article | |||

| SM-146 | SM-168 | SKR-60 | SKR-73 | |

| Length, mm | 750 | 750 | 1366 | 2070 |

| Diameter of body, mm | 121 | 139 | --- | --- |

| Diameter with rams in the transportation position, mm | 143 | 163 | 37-48 | 42-57 |

| Connection thread: - upper clutch as per GOST 633-80 - lower nipple as per GOST 633-80 |

NÊÒ-73 NÊÒ-73 | NÊÒ-89 NÊÒ-89 |

It is hanged on the rope | It is hanged on the rope |

Upward