PRODUCTS

CATCHER

CATCHER OF DRILL RODS LShPM2UNIVERSAL CATCHER OF DRILL RODS LShU

CATCHER OF SHAFT LV-120

CATCHING MAGNET OF TYPE ML

CATCHERS ECN (LCN)

MAGNETIC JET JUNK BASKET (MSM)

JUNK RETRIEVER MShU

SLUDGE TRAPS UMK, ShMU

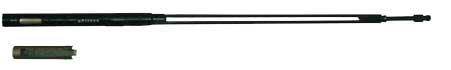

CATCHER OF DRILL RODS LShPM2 |

|

| are designed for fishing of unscrewed or fallen but not stuck sucker-rods inside tubing during the routine well repair. These fishing tools are designed to be used in all macroclimatic regions in accordance to GOST 16350-80. |

Specifications | LShPM2-73 | LShPM2-89 |

| Diameter of tubing strings in which fishing is taken place, mm | 73 | 89 |

| Diameter of sucker rods to be fished, mm | 16, 19 | 16, 19, 22 |

| Max safe koad at fishing tool, kN | 40 | 55 |

| Rod connection thread in accordance to GOST 13877-80 | SH19 | SH22 |

| Length, mm | 1820 | 1950 |

| Puter diameter, mm | 56 | 68 |

| Complete set weight, kg, no more than | 7 | 12 |

UNIVERSAL CATCHER OF DRILL RODS LShU |

|

|

The universal catcher of drill rods is intended for catching drill rods in the stand of pump and compressor pipes with the hook

(seat) catching the elements of thread connection –clutch, thrust and supporting shoulders on the head of drill rod for

the case of existence of significant ASP deposits in the NKT. The catchers are intended for operations in all macroclimate

regions as per GOST 16350-80. In comparison with catchers of other constructions the catcher LShU 73-22-16 has the following advantages:1. It has bigger carrying capacity, which cannot be achieved by the catchers with a conical coupling of slip socket with the body;2. In order to catch, the existence of extended cylindrical surface on the caught end of drill rod is not required; 3. It catches a hardened TVCh clutch which is engaged reliably by the teeth of slip catchers; 4. It catches, when the form and real cross dimensions of any caught element significantly differ from the nominal in cases of worn clutches, and heads of drill rods with insufficient heading; 5. It catches passing the body of drill rod through the body; 6. It has small resistance to lowering into NKT with ASP deposits; 7. The caught drill rod is freed easily on the surface. |

Specification

| Code of catcher standard size | LShU 73-22-16 | LShU 60-19-16 |

| Diameter of NKT, mm | 73 | 60 |

| Diameter of fishing pump rods, mm | 13, 16, 19, 22 | 13, 16, 19 |

| Diameter of thorough through flowing channel, mm | 32 | 22 |

| Connection thread of rods as per GOST 13877-80 | Sh19 | Sh19 |

| Diameter of taken up clutches or clamps of pump rod, mm | 24-46 | 24-38 |

| - with a collet 22 mm | 40-46 | |

| - with a collet 19 mm | 36-42 | 32-38 |

| - with a collet 16 mm | 32-38 | 28-32 |

| - with a collet 13 mm | 24-30 | 24-30 |

| Length, mm | 1765 | 1770 |

| External diameter, mm | 58 | 47.4 |

| Weight of complete set, kg | 7,5 | 6,6 |

|

CATCHER OF SHAFT LV-120Purpose:The catcher of shaft is intended for catching and removing the shaft of submersible motor of type PED-117Structure:The catcher of shaft consists of an adaptor, a body, a collet and a mill cone executed in the form of washover shoe. The scratch is made on the internal catching surface for catching a removed item. The spring features of the collet are provided by several blind slots. The circulation holes and channels are made in the mill cone, they are intended for circulating fluid and provide better cooling and effective removal of chips. Catching of the shaft is performed when removing the catcher due to moving the collet along the inclined surface of body and its jamming between the body and external surface of the shaft. |

Specification

| Code of catcher of shaft standard size | LV-120 |

| External diameter, mm | 120 |

| Connection thread, GOST R 50864-96 | 27820 |

| Maximum value of nominal size for a collet catcher, mm | 25,4 |

| Working range of catcher in relation to nominal size, mm | +0,8/-1,0 |

| Length, mm | 490 |

|

CATCHING MAGNET OF TYPE MLPurpose:The magnet catcher is intended for removing small items with ferromagnetic features from the oil, gas and geological exploration bores. Structure:The magnetic catcher consists of a body, an adapter, a magnetic insertion and a cone. The cones have three variants of execution: the short cone, the long cone, the cone executed in the form of washover shoe with the welding of tungsten carbide. The thorough channels are made in the magnetic insertion to pass circulating fluid. There are left and right catchers. |

Specification

| Code of standard size | ÌË-82 | ÌË-89 | ÌË-102 | ÌË-114 | ÌË-118 | ÌË-127 | ÌË-135 | ÌË-140 | ÌË-146 | ÌË-152 | ÌË-170 | ÌË-188 | ÌË-198 | ÌË-203 | ÌË-243 | ÌË-292 | ÌË-295 |

| 1. Internal diameter of cone, mm | 60 | 60 | 82 | 72 | 72 | 80 | 80 | 120 | 99 | 104 | 150 | 168 | 178 | 143 | 179 | 224 | 224 |

| 2. Conventional carrying capacity, kg, not less than | 215 | 215 | 350 | 350 | 350 | 550 | 550 | 700 | 700 | 700 | 700 | 900 | 900 | 900 | 900 | 2180 | 2180 |

| 3. External diameter, mm | 82.6 | 89 | 102 | 114.3 | 117.6 | 127 | 135 | 140 | 146 | 152.4 | 170 | 188 | 198 | 203.2 | 243 | 292.1 | 295 |

| 4. Connection thread | 3-66 | 3-73 | 3-76 | 3-76 | 3-76 | 3-76 | 3-76 | 3-88 | 3-88 | 3-86 | 3-88 | 3-117 | 3-117 | 3-117 | 3-147 | 3-152 | 3-147 |

|

CATCHERS ECN (LCN)The catchers ECN (LCN) are intended for catching the electric centrifugal pump, taking its catching head or the body of pump in the capital string. There are left and right catchers. |

Specification

| Designation | External diameter, mm | Diameter of caught ECN, mm | Connection thread as per GOST 28487-90 |

| LCN-123/92 | 123 | 92 | Ç-86 |

| LCNL-123/92 | 123 | 92 | |

| LCN-123/92/95 | 123 | 92...95 |

|

MAGNETIC JET JUNK BASKET (MSM)It is intended for removing small metallic objects from the bottom of oil and gas bores. The MSM uses high-energy magnets, coercitive force of which is practically 10 times higher than the force of magnets used before.

|

Specification

| Standard size | Diameter, mm | ||

| Production string | Body, Dk | of boring head, Dfn | |

| MSM-112 | 140-146 | 108 | 112 |

| MSM-130 | 168 | 127 | 130 |

| MSM-180 | 219 | 170 | 180 |

| MSM-200 | 245 | 190 | 200 |

| MSM-275 | 324 | 235 | 275 |

| MSM-330 | 377 | 235 | 330 |

| MSM-374 | 426 | 235 | 374 |

|

JUNK RETRIEVER MShUThe implosive junk retriever is intended for:- removing foreign objects from the bottom of the bore, including non-magnetic ones with a weight of 20 kg; - cleaning the "head" of caught tool after cutting. Design features:- possibility of washing and reaming the well bore in the course of lowering;- response only in response to a command from the surface (through the channel of pipes); - minimum time of preparation at the drill site (15 minutes maximum); - time of breakdown elimination (performing of fishing operations) – 10 minutes, maximum. |

Specification

| Parameter of specification, dimensionality | Modification, value | |||

| MShU-90.1 | MShU-114.1 | MShU-172.1 | MShU-195.1 | |

| Minimal size of caught particles, mm | 5 | |||

| Maximum drift diameter of catcher, mm | 68 | 85 | 130 | 150 |

| External diameter of body , mm | 89 | 114 | 172 | 195 |

| External diameter of boring head , mm | 90 | 114 | 185 | 210 |

| Length, m | 6,72 | 7,12 | 6,28 | 6,26 |

| Connection thread | Z-73 GOST 28486-90 | NKT 73 GOST 633-80 | Z-133 GOST 28486-90 | Z-133 GOST 28486-90 |

| Weight, kg | 160 | 250 | 500 | 625 |

|

SLUDGE TRAPS UMK, ShMUThe sludge traps are intended for catching and removing metal junks from the bottom in the course of drilling. The sludge trap consists of the body with two internal connection threads and one external erecting left thread, to which the trap is threaded. The internal surface of the trap is executed in the form of left square thread. The sludge trap may be operated for rotor and turbine methods of drilling. For operation, the sludge trap is installed in the arrangement of the drill stem lower part right above the boring head. During operation the liquid flow lift particles of metal junk, which getting in the internal part of catcher through the left flat thread are rejected in the lower part of the catcher. Spinning and unscrewing components of the sludge trap, its fixations and breakouts in the arrangement of lower part of the drill stem is performed by rotary tongs when the rotor is braked. |

Specification

| Parameters | Code of article | |

| UMK-215,9 | UMK-194 | |

| External diameter, mm | 215,9 | 194 |

| Length, mm | 700 | 700 |

| Weight, kg | 71 | 66 |

| Maximum allowed axial stress, kN | 250 | 250 |